|

Starion

turbochargers |

| |

|

|

Starions used 6 different turbochargers

depending on engine and market

1) TC06-11A (8 cm2 turbine housing) non intercooled

4G63 2.0 litre SOHC (Australia, JDM, Europe)

2) TC06-11A (8 cm2 turbine housing) intercooled

4G63 2.0 litre SOHC (Australia, JDM, Europe)

3) TC05-12A (6cm2 turbine housing) non intercooled

JDM 4G63 2.0 litre SOHC (JDM)

4) TC05-12A (6cm2 turbine housing) intercooled

JDM 4G63 2.0 litre SOHC (Australia, JDM)

5) TD05-12A (8cm2 turbine housing) non intercooled

4G54 2.6 litre (USA, JDM, Europe)

6) TD05-12A (8cm2 turbine housing) intercooled

4G54 2.6 litre (USA, JDM, Europe)

The intercooled and non-intercooled turbos

had the same wheels but the compressor housing was different.

The compressor outlet was different to enable connection of the

intercooler hose. Because of this the wastegate actuator was

also different.

Also there were watercooled and non-watercooled

versions for some models.

|

|

|

TD05-12A turbo (with intercooled

type compressor housing) |

|

|

Turbo

comparison and identification |

|

Turbo compressor housings.

Australian JA,JB Starion uses 4G63

SOHC engine with a TC06-11A (left hand pic)

Various Japanese domestic market (JDM)

4G63 SOHC used TC05-12A.

|

|

TC06-11A compressor wheel on the left

TC05-12A compressor wheel on the right. |

|

JDM TC05 housing compared to

TCO6. Dimension shown only to highlight obvious external size

difference of the housing and hence internal size/area. |

|

Identification number are on

the housings |

|

|

| Australian

spec 4G63 SOHC 2.0 Starion used TC06-11A turbo with 8cm2 (080)

exhaust. The US market G54B 2.6 Starion/Conquest used the TD05-12A

however with a 8cm2 (080) exhaust housing. The Japanese market

4G63 SOHC 2.0 Starion used a TC05-12A (same size turbine wheel

as US) however with the much smaller 6cm2 (060) exhaust housing. |

|

|

TC06 turbine 8cm2 (080) housing

on the left and TD05 8cm2 (080) housing on the right. |

|

TC06 turbine 8cm2 (080) housing

as used on 4G63 2.0 SOHC 8 valve Australian spec Starions. |

|

TD05 turbine 8cm2 (080) housing

as used on G54B 2.6 US Starion/Conquests

. Notice smaller diameter. Entry slot

into involute is also 1mm narrower.

|

|

Another shot TC06 on the left

TD05 on the right. |

|

TC06 turbine wheel on the left

and TD05 turbine wheel on the right |

|

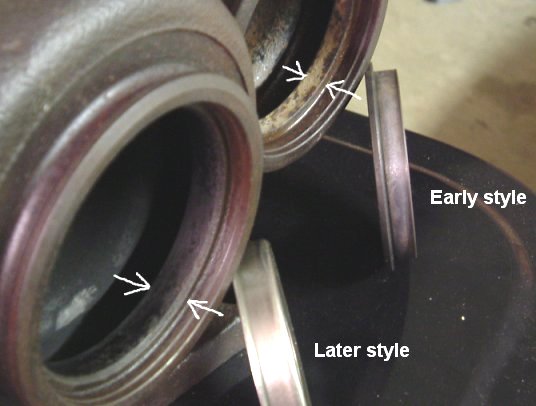

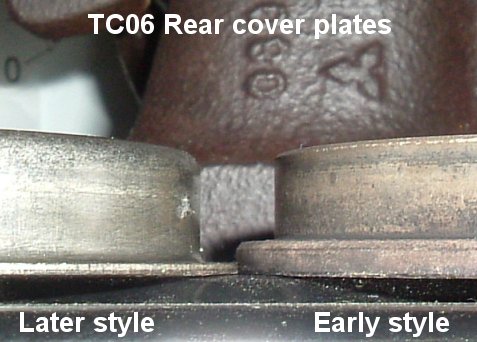

There are minor differences

between early and late TC06 turbine housings. However the centre

cartridge is the same and is interchangable providing the correct

cover plate is used.

(Note: to change the cover plate the

turbo centre cartridge has to be pulled apart)

|

|

|

Special Stuff |

|

|

Ralliart TD06-19C turbo used

on factory Pajero/Starion G54B 2.6 litre 330hp spec race engine.

This is the same turbo used on 1988 Paris-Dakar Ralliart Pajero.

These turbo's were used by the factory

teams only and were not for sale.

Wastegate actuator has only a 300

Kpa (0.3 bar) spring. Boost was controlled by the ECU. This could

be changed in the cockpit by means of a switch.

|

|

1988 Paris-Dakar Ralliart Pajero!

Full kevlar body spaceframe construction

200Km/h + on the sand!

|

|

Side view. Note lack of water

cooled centre bearing housing. |

|

Rear view. A separate pipe was

used for the wastegate and joined the main exhaust about a metre

down the engine pipe. |

|

This view shows there is no

provision for wastegate passage to main exhaust outlet so seperate

dump pipe for wastegate must be used. |

|

This is the Ralliart exhaust

G54B 2.6 manifold shown with the turbo above. Notice size of

turbo outlet. |

|

This is a standard 2.6 G54B

turbo exhaust manifold.(notice weld repair) |

|

This view shows the sealing

ring from the standard G54B manifold above you can see how much

bigger the Ralliart manifold turbo outlet is.

ID on standard manifold is 43.2mm.

Ralliart manifold is 54.2mm.

|

| |

|

|

This is exhaust manifold

from 4G63 2.0 SOHC engine. Turbo outlet is exactly the same size

as stock G54B. |

|

|

Turbo Testing

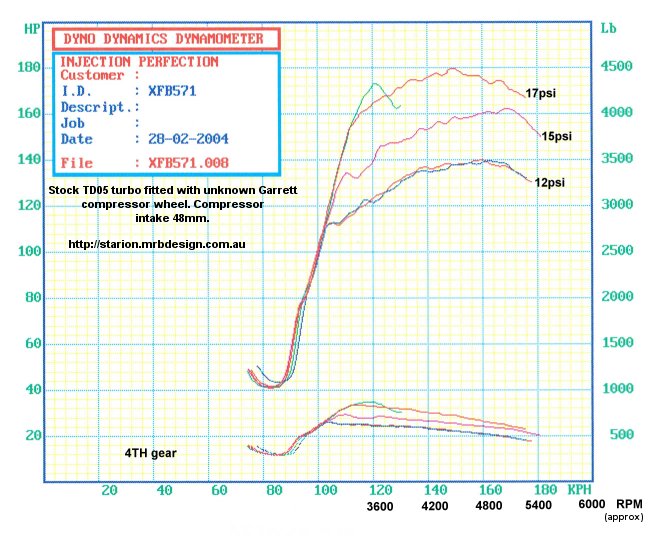

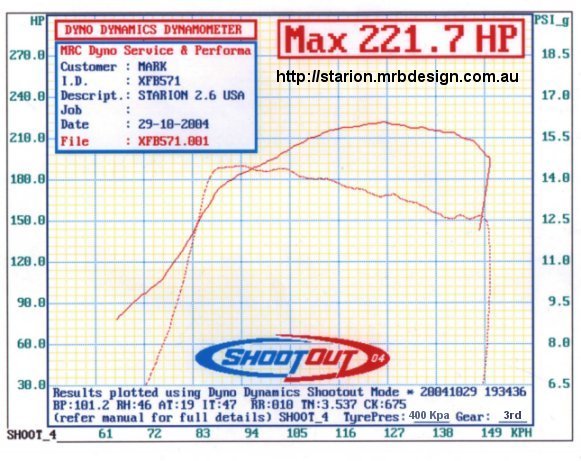

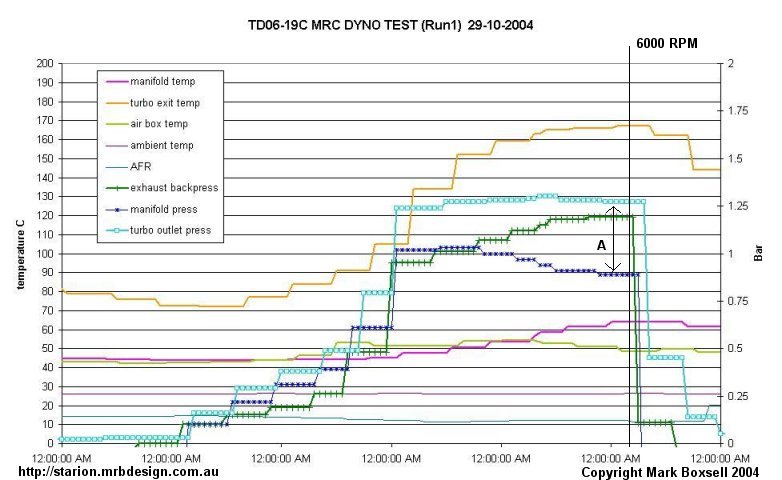

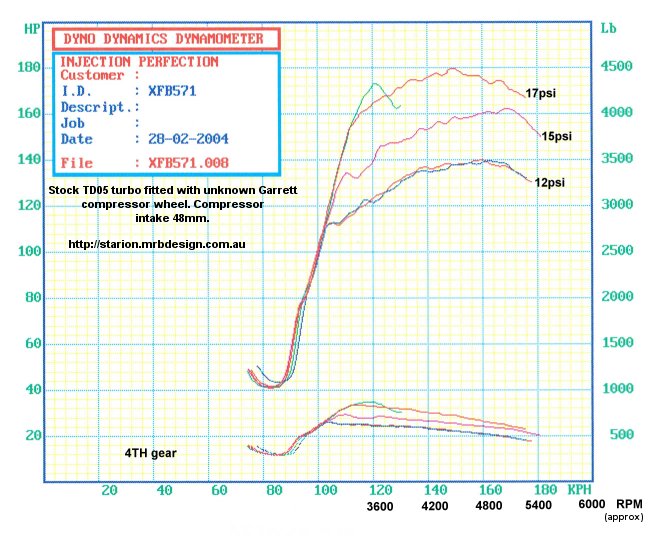

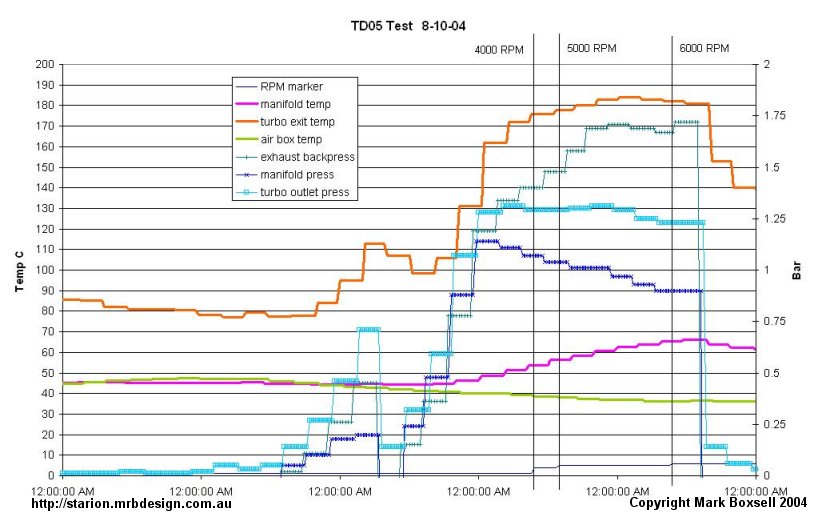

I did some testing before and after

fitting the Ralliart TD06-19C. The first graph shows data recorded

using the "high flowed" TD05. Compressor housing was

modified and a Garrett compressor wheel was fitted. Turbine side

was stock. My horsepower has increased by somewhere around (I

say around because the previous best with the TD05 was 180HP

and the test was done in 4th gear) 40HP at the wheels with NO

other changes other than to connect the different exhaust flange.

I'm running a ported Magna head, Camtech cam (Camtech is an Australian

cam company), full 3" exhaust, standard ECU, standard airflow

meter. Being an engineer I decided to do some data logging to

see what the difference was between the turbos. See graphs below.

Due to my limited budget I purchased low cost DAQ gear that could

only sample at about 6-8 samples a second that's why the graphs

have steps but the info is still there to see. There is no RPM

trace on the graphs so I added some RPM markers.

|

|

|

Starion on the dyno at MRC Dyno

located in Sydney Australia. |

|

|

Engine bay pic with TD06 turbo

fitted. |

|

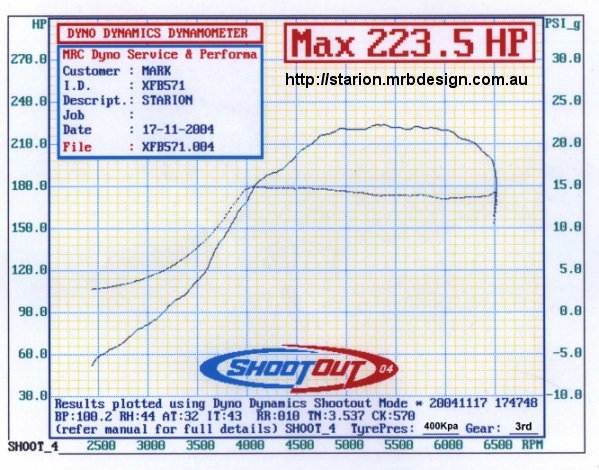

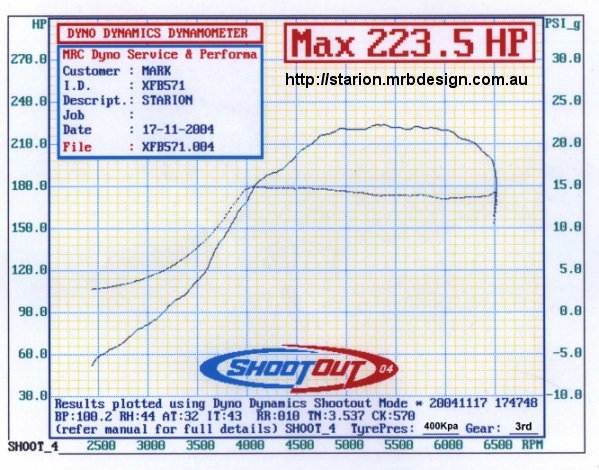

TD05

Dynosheet

|

| |

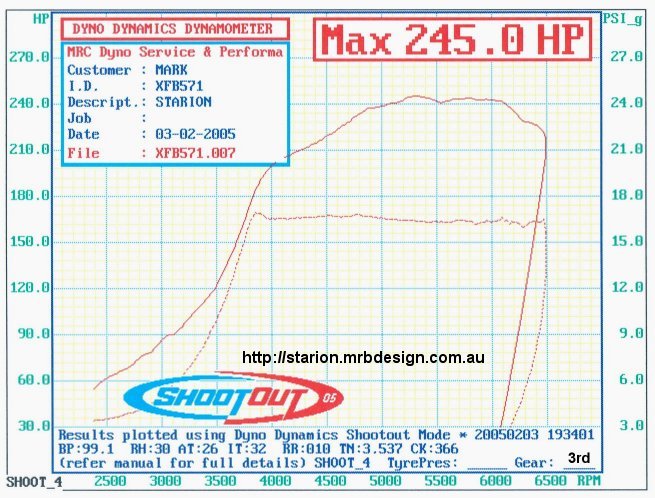

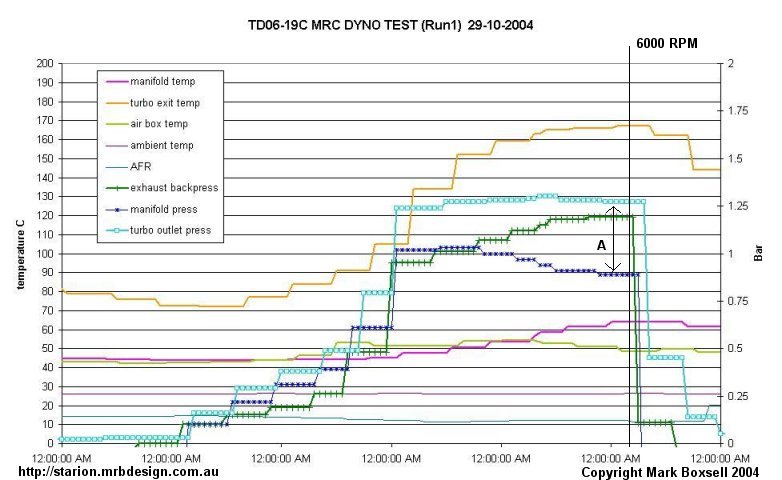

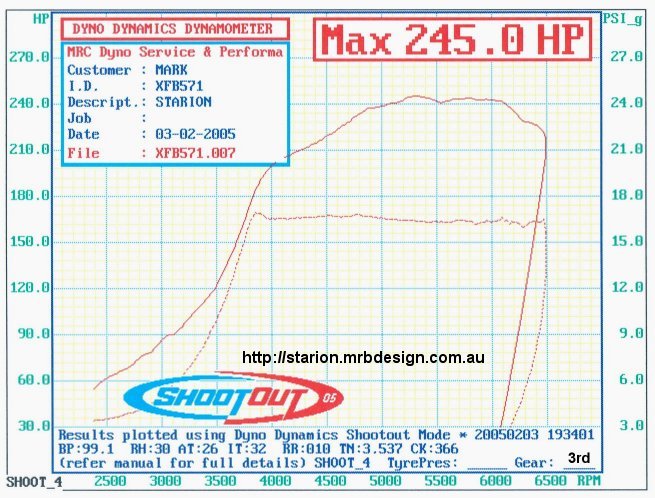

TD06-19C

Dynosheet

|

|

NOTE: TDO5 was "high flowed"

and fitted with a Garrett compressor wheel by previous owner.

Turbine side was untouched. |

|

Note it is making 221 HP on

only 13 psi. |

|

The main difference between the turbos was:

1) Reduction of exhaust manifold backpressure by 0.5 bar (7.25

psi) @ 6000 RPM!!!!

Uncorked!!!!

2) Reduction in compressor outlet temperature

of approx 20 degrees C

Note: this is with a lot higher airflow as well.

Another discovery is the major restriction

between the turbo outlet and the inlet manifold. There is about

a 3.8 psi pressure drop through the TBI (with 220HP airflow)

noted as "A" in the graph.

The engine wants to really rev now pulls hard

to 6500 RPM even with the boost dropping off as shown in the

graphs. Note the wastegate is connected to the "hard pipe"

so keeps the pressure constant there.

|

|

|

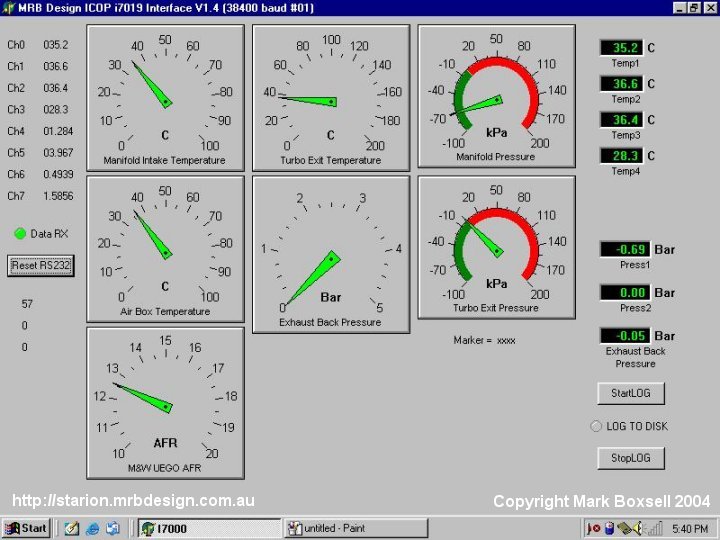

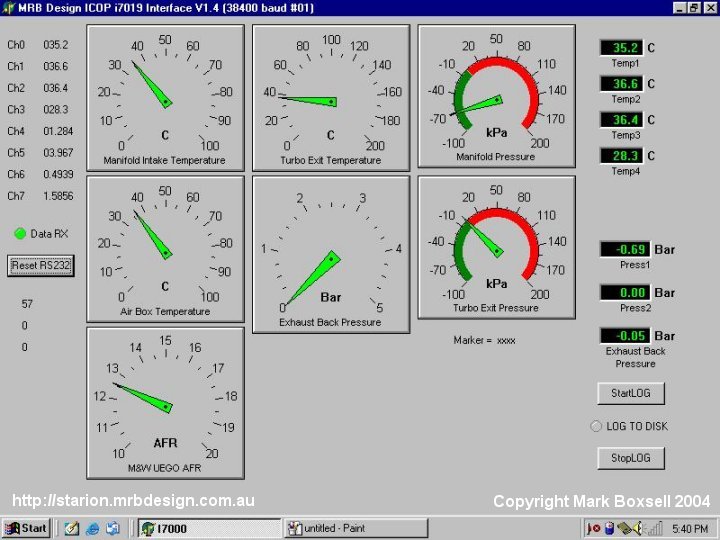

Briefcase DAQ system I built

using 3 bar Delco MAP sensors, M&W Uego wideband controller

(not shown) and ICP i7000 modules. |

|

I wrote the software using Borland

Delphi. |

|

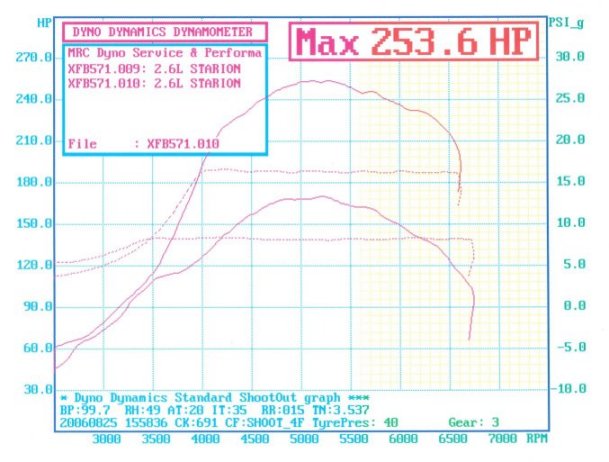

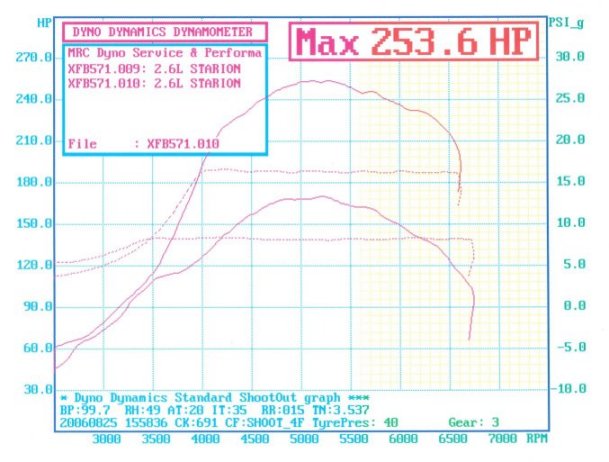

Another run with a fraction

more boost and the wastegate hose relocated to the inlet manifold

(was in cross-over pipe).

Note: abrupt roll off at 6500 RPM

is dyno operator backing off.

|

|

HKS EVCIV fitted boost increased

to17 psi with factory air cleaner removed and POD filter (no

airflow meter) and Haltech F3. |

|

POD filter could be installed

better but was installed quickly for dyno run. |

|

Magna MPI

installed

|

|

Magna MPI

dyno sheet.

This does not tell

the whole story the

drivability is vastly

better compared to

the stock TBI setup.

|